Market declarations overview

Market declarations can be altered in many places in snapPacking and flow from that point on. Market declarations only apply to pipfruit, but is driven from SETUP -> Produce types that have been ticked to Use market declarations.

Groups of requirements

Although there are many market requirements (1,296 at time of writing), most of these are in a handful of groups that can be managed similarly:

Inclusions - this group has a requirement for each market. These are usually ticked by default and seldom unticked. Only untick if there is some otherwise unhandled issue that prevents fruit being suitable for the particular market.

Packaging - these requirements are manually ticked for specific pallets just prior to loadout. These include declarations that country-specific language labels have been applied. They are usually updated by scanning pallets into a

STORAGE -> Joband updating declarations for that job once complete.PCR - requirements relate to bin submissions based on spray diary clearances that are usually ticked automatically. Investigate issues by comparing the harvest date on a

Bin submissionagainst the PCR clearance date inMASTER DATA -> PCRfor the same orchard/management area/variety. PCR clearances are published by CropSure and imported into your portal early each morning. You can also manually check for updates to clearances by running the appropriate task inSETUP -> Tasks.Pests - this largest group of requirements is managed as part of QC Lot inspections. You won't see pest declarations ticked as met until the QC lot stage - at which point all pest requirements are assumed to be met ...until a problem is found. Based on your

QC defect setupsnapPacking will recommend pest declarations are unticked if pests are found during lot inspections. Pest downgrades still need to be actioned manually by your quality staff.Registers - these requirements relate to production sites and are ticked automatically based on orchard information published by NZ Apples and Pears. During the season, production sites are regularly removed from the official registers on the

MPI websiteso we recommend you schedule regular checks for changes to the orchard information (SETUP -> Tasks). Any register declaration changes are made at theProduction sitelevel and will ripple through all stock from that production site.USA and Japan blocks - these requirements relate to

Pre-shipment blocksand will be ticked automatically when the related block passes.Shipment within 42 days - these require fruit to be re-inspected for particular defects if pallets are not shipped within 42 days (M fructicola for Russia and N Alba for China). Pallets in stock for longer than 42 days will automatically have these declarations unticked. They will be ticked again for a further 14 days if samples are recorded in

QUALITY -> Storage Lotsfor all production sites on the pallet.Maturity (China SPI) - this single requirement for China (and Australia) must be ticked manually once an appropriate maturity sample has been taken. This can be applied to all management areas for the sampled production site and variety (in

SETUP -> Orchard blocks).Other manual requirements - there are some other requirements that need manual assessment and declarations recorded at an appropriate level. At the time of writing these include:

- "Fruit has been sourced from low ALCM population orchards" (Japan). This could be ticked at the

Orchard or Production sitelevel. - "Residue test certificates are available to send with consignment" (Russia). Tick at the highest appropriate level based on the available residue certificates.

- "Fruit has been sourced from low ALCM population orchards" (Japan). This could be ticked at the

Places you can edit declarations

SETUP -> Orchard blocksfor requirements that apply to all fruit from either an orchard, production site, or a specific management area/variety. Declarations can be edited from the Market declarations drop-down menu.STORAGE -> Bin submissionsfor requirements that apply to fruit on specific bin submissions. This is where PCR requirements can be declared by comparing the harvest and clearance dates. Declarations are edited on the Declarations tab.PACKING -> Runsis not a common place to edit declarations but might be convenient if all fruit from the run needs to be removed from a market for some reason. Declarations are edited on the Declarations tab.QUALITY -> QC Lotsis the most common place to edit declarations based on packhouse pest findings. Declarations for the QC lot (or the entire packing run) can be edited in from the Actions drop down menu.STORAGE -> Jobsare used to update declarations for a collection of pallets once the job is completed (eg applying laguage labels prior to shipment). Edit declarations from the Declarations drop down menu.TOOLS -> Edit store items declarationsallows declarations to be edited for a random collection of bins or pallets. The list of item codes to be updated can be pasted in from anywhere (including Excel).- Individual bins or pallets can also have their declarations edited from the Search results page (Actions dropdown menu). Search for a pallet or bin number using the search box on the top of the menu bar.

Permissions

Permissions for which user roles are allowed to edit particular declarations are controlled from SETUP -> QC permissions

Changing declarations

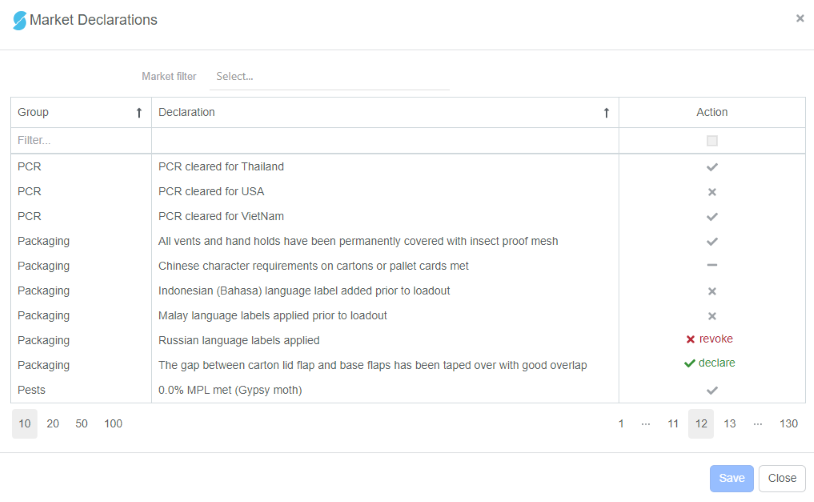

When you edit declarations, you will be taken to a screen which shows all declarations.

The icons in the Action column indicate what the status is for the batch of bins/pallets you have selected:

- all bins/pallets have this declaration ticked.

- all bins/pallets have this declaration ticked. - all bins/pallets have this declaration unticked.

- all bins/pallets have this declaration unticked. - the bins/pallets have a mixture of ticked and unticked.

- the bins/pallets have a mixture of ticked and unticked.

To declare or revoke a declaration, click on the icon. Press Save. You will be prompted to provide a detailed reason for these changes. Once entered, press Accept actions.

Declaration history

A history of all declaration changes can be found in QUALITY -> QC Lots -> Setup menu -> Declaration history. Additionally, for individual bins/pallets, you can see the history on the Search results page.

Reasons for Market failure

To see reasons why a pallet or bin is not suitable for a market, use the TOOLS -> Market failure query tool.